We take great pride in our ISO 9001:2015 certification by delivering quality results every time. Quality is inherent to our culture which promotes a sense of pride with every piece produced. Our Quality Policy reinforces our dedication to our customers and community.

What’s the true cost of quality to you? Does poor quality delay your production schedule? Does it consume other resources that could be working on more productive tasks? How are future sales affected by a quality failure in the field?

Do you get print or tolerance errors pointed out, before the parts are made?

Quality Policy

To be a trusted and dominant source for your production milling and turning needs and to keep business moving forward while maintaining our commitment to continuous improvement.

Get Started

Contact us to discuss your next project

First in Service

It is our goal to be an integral, seamless part of your team. Our can-do attitude makes it easy to do business with us, whether it’s machining samples, making design suggestions, adjusting shop schedules, or accommodating inventory.

How does a late shipment affect you? Does it result in production delays? Does it result in unbudgeted overtime? Does it result in expedite fees or expedited shipping costs? Do you get suggestions on cost savings? Do you get help during initial design stages, to reduce cost and time?

We strive to ensure a team mindset by working with our customers to make it easy to do business with us and guide you through our process.

Contact us today to inquire about your next project

First In Profitability

First Manufacturing provides a unique capability of consultation that results in increased profitability for our customers:

- We can provide insight as to the most efficient way to manufacture a part

- We offer design assistance of components for the easiest and least expensive way to manufacture

- We are knowledgeable, straight-forward, and easy to work with

- We research new machining processes and methods, offering continuous improvement

First In Profitability

We have over 20 years of Manufacturing Engineering and Design experience. The owners use Mechanical Engineering degrees and years of Machining and Manufacturing Engineering experience to provide high quality manufactured parts, on schedule, with the ultimate customer service and communication.

Our Equipment

The first part of the job is having the right equipment to do it.

Experience Matters

We have over 25 years of Manufacturing Engineering and Design experience. The owners use Mechanical Engineering degrees and years of Machining and Manufacturing Engineering experience to provide high quality manufactured parts, on schedule, with the ultimate customer service and communication.

Quality Policy

To be a trusted and dominant source for your production milling and turning needs and to keep business moving forward while maintaining our commitment to continuous improvement.

Free Consultation

Contact us for your next project!

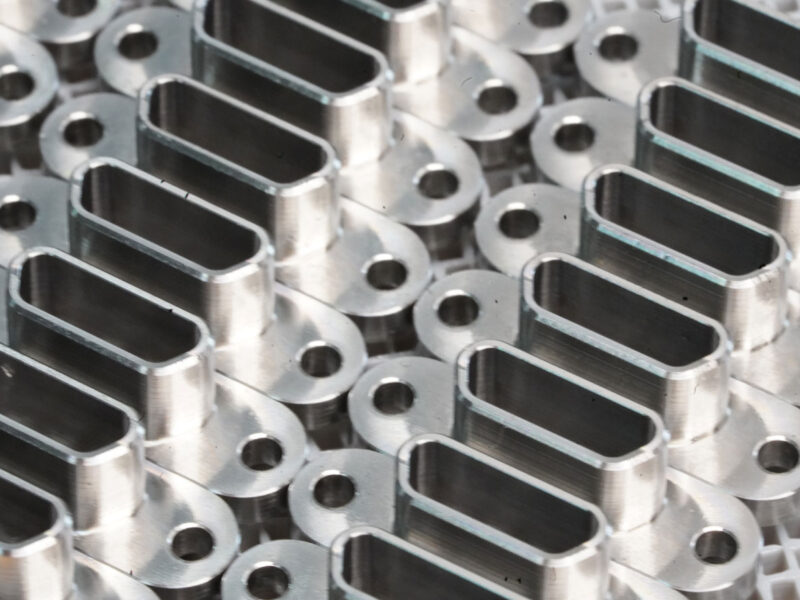

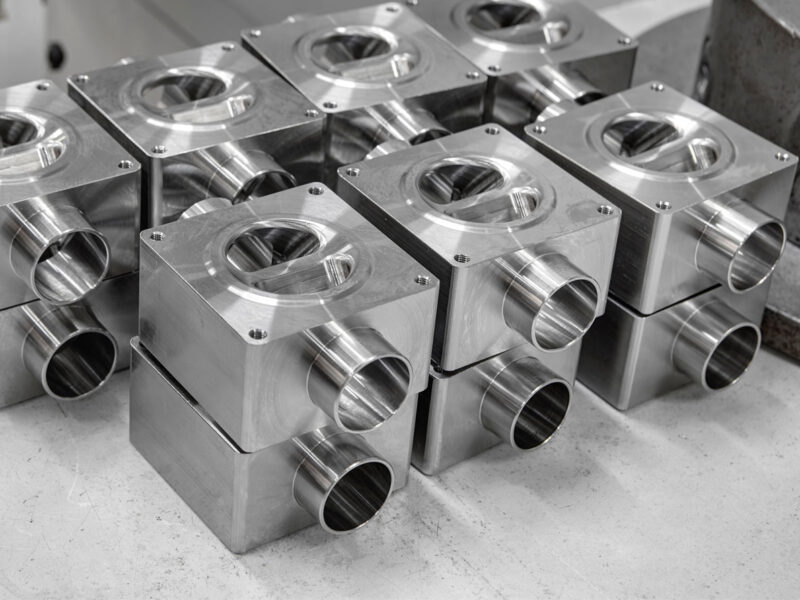

Milling & Turning

We pride ourselves in having an arsenal of state-of-the-art equipment. We are constantly learning and improving our manufacturing process.

Full ERP Shop System

We have invested in technology to be more accurate, efficient, and productive.

Quality Management System

Our ISO 9001:2015 certification helps ensure we deliver quality and consistency every time.

Assembly Services

Our assembly services help save time by being able to delivery not just a product--but a turnkey solution you can depend on.

- Design Assistance

- ISO 9001:2015 Certified

- Cutting Edge Equipment

First Manufacturing began part time in January 2003, in Rocklin, California, with a manual mill and a manual lathe. In October of 2003, the business moved to Sioux Falls, South Dakota, and began expanding its machining capability. From May 2004 through the present, capital equipment has been added to increase productivity and efficiency, and expand capability. First Manufacturing became a full-time venture in August of 2006. First Manufacturing purchased Specialized Machine in 2019, adding over 10,000 square feet of shop space and additional milling and turning capabilities.

Now, with a full staff of machinists and operators and a wide range of CNC machines with varying capabilities, First Manufacturing is ready to partner with you for all you machining needs.

We have over 15 years of Manufacturing Engineering and Design experience. The owners use Mechanical Engineering degrees and years of Machining and Manufacturing Engineering experience to provide high quality manufactured parts, on schedule, with the ultimate customer service and communication.

We strive to make it easy to do business with us. Whether it’s machining samples, making design suggestions, adjusting shop schedules, or accommodating inventory, it is our goal to be an integral, seamless part of your team.

What our customers are saying:

“The spindle pins look awsome! You really did a great job on these. Thanks!”

- Aftermarket Automotive Supplier

“Our QC guy finished inspecting that first run of front panels. He commented about the parts by stating that every dimension he’s seen on Specialized Machine’s parts has been right in spec. He has not seen anything more than .001-.002” from nominal.”

- Supplier of Electronic Test Equipment

“Thank you for all of your help in getting this new product launched. The parts look great!”

- Medical Supplier

“The spindle pins look awsome! You really did a great job on these. Thanks!”

- Aftermarket Automotive Supplier

“Our QC guy finished inspecting that first run of front panels. He commented about the parts by stating that every dimension he’s seen on Specialized Machine’s parts has been right in spec. He has not seen anything more than .001-.002” from nominal.”

- Supplier of Electronic Test Equipment

“Thank you for all of your help in getting this new product launched. The parts look great!”

- Medical Supplier

“The spindle pins look awsome! You really did a great job on these. Thanks!”

- Aftermarket Automotive Supplier

“Our QC guy finished inspecting that first run of front panels. He commented about the parts by stating that every dimension he’s seen on Specialized Machine’s parts has been right in spec. He has not seen anything more than .001-.002” from nominal.”

- Supplier of Electronic Test Equipment

“Thank you for all of your help in getting this new product launched. The parts look great!”

- Medical Supplier

- © OpenStreetMap contributors.